CNC AUTOMATIC ROTARY

POLISHING MACHINE

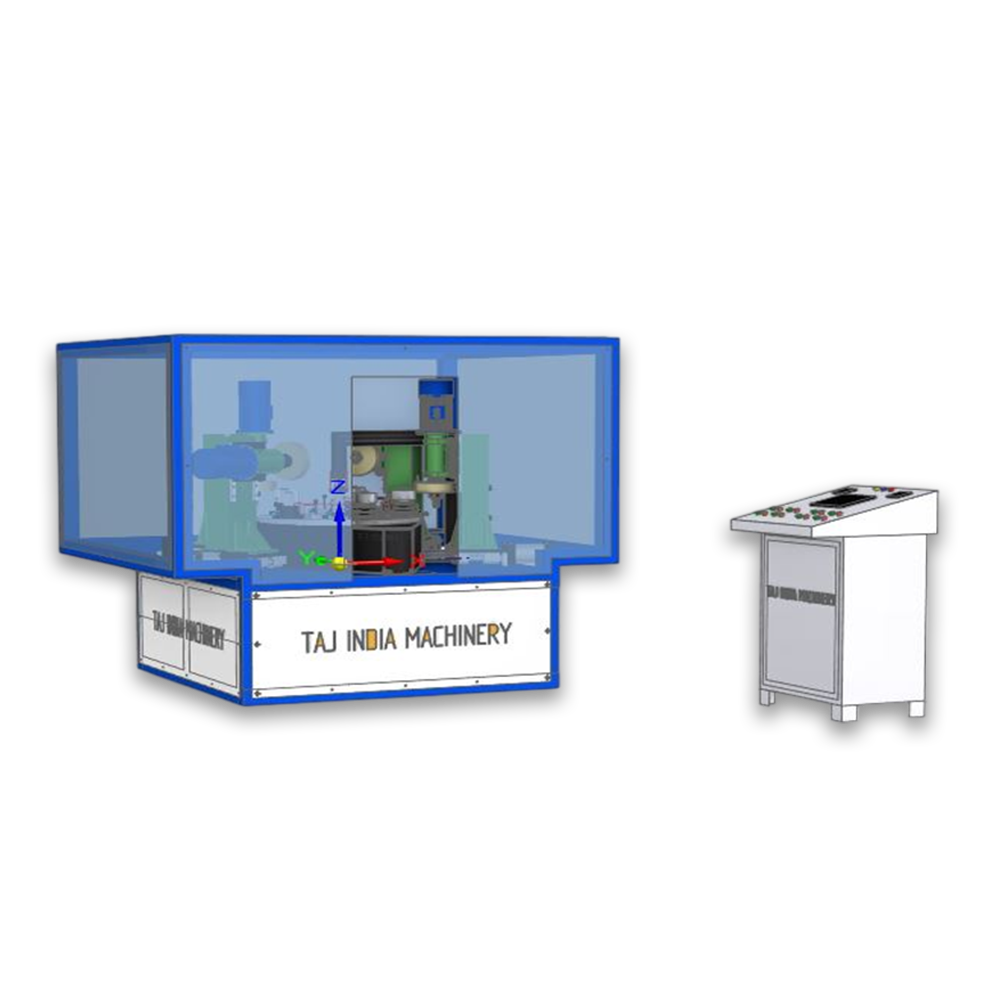

CNC AUTOMATIC 4 STATION ROTARY POLISHING MACHINE (TI-RTRY-4AIR)

l

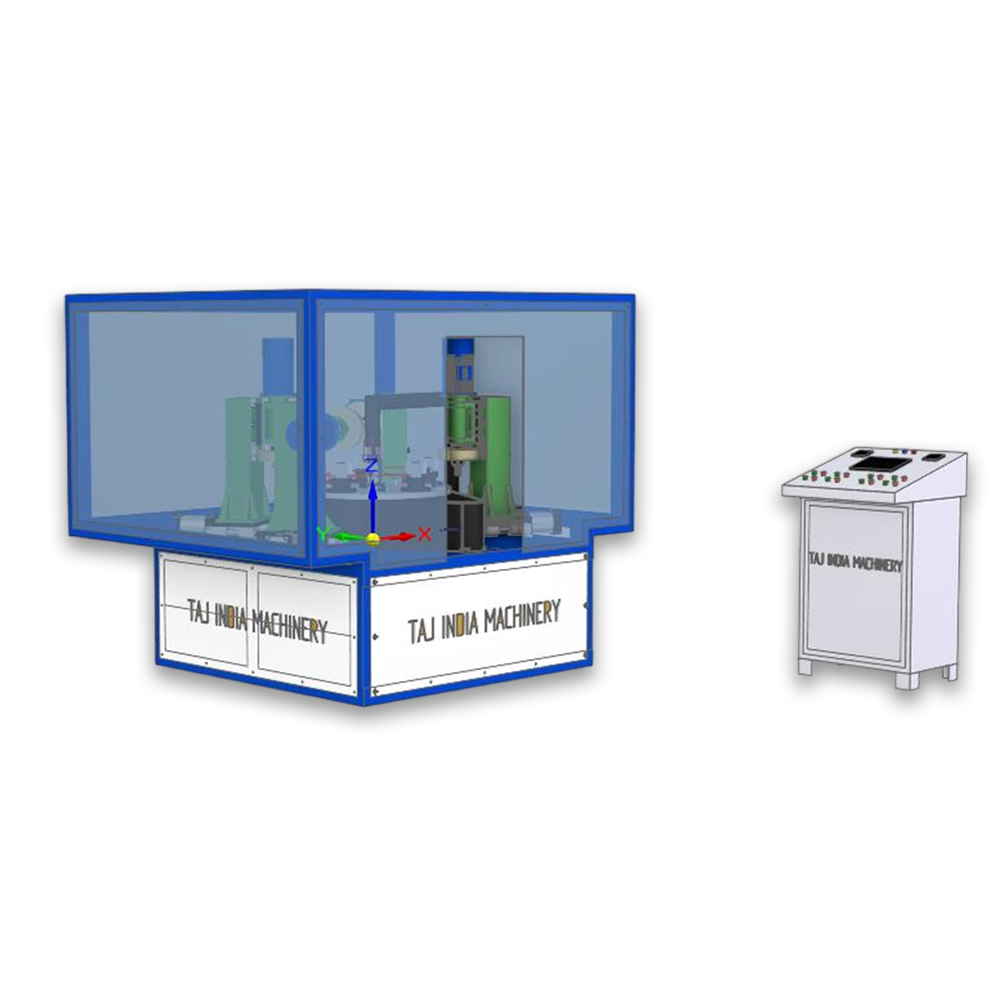

CNC AUTOMATIC 6 STATION ROTARY POLISHING MACHINE (TI-RTRY-6AIR)

l

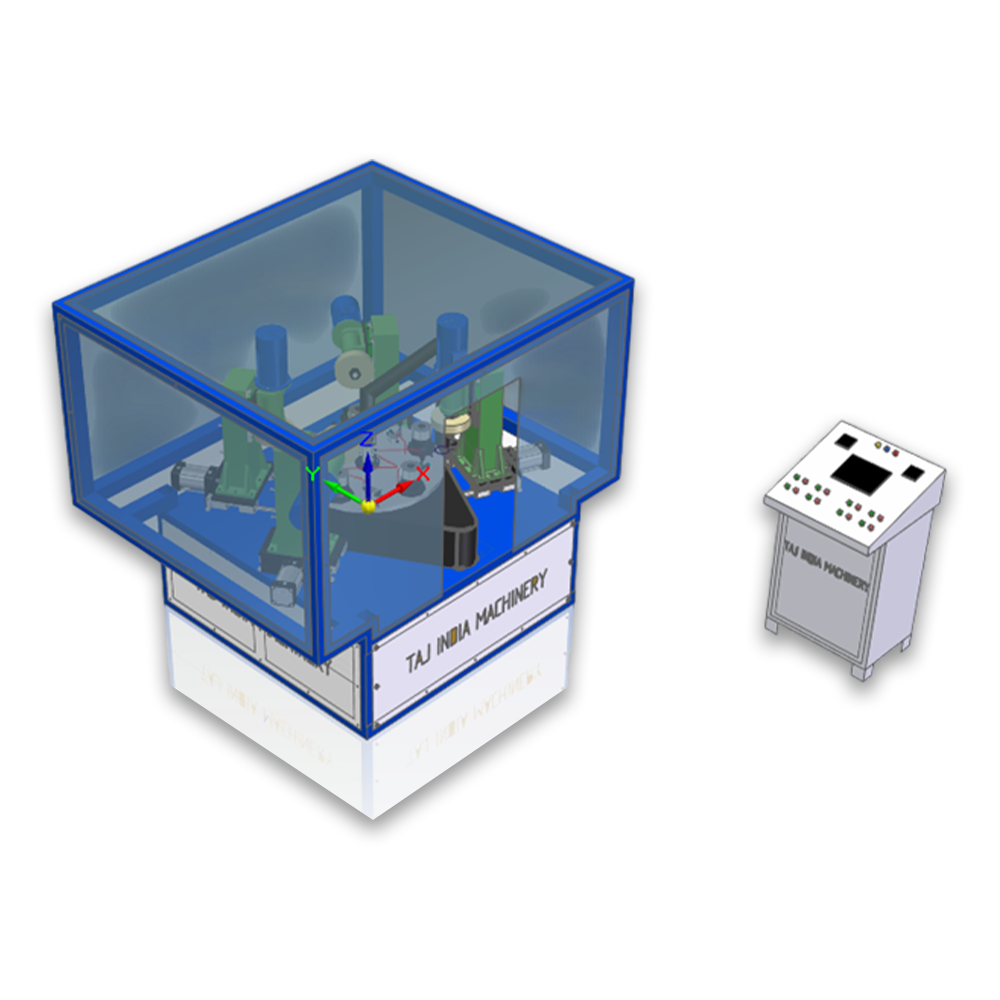

CNC AUTOMATIC 8 STATION ROTARY POLISHING MACHINE (TI-RTRY-8AIR)

l

Taj India Machinery – Leading CNC Automatic Rotary Polishing Machine Manufacturer

When it comes to precision surface finishing and high-speed metal polishing, Taj India Machinery stands as one of the top manufacturers and exporters of CNC Automatic Rotary Polishing Machines in India. Our advanced CNC-controlled polishing machines are designed to deliver unmatched accuracy, efficiency, and productivity for a variety of metal polishing applications.

With decades of engineering expertise and innovation, Taj India Machinery has become a trusted brand among industries that demand flawless finishing — from stainless steel kitchenware and cookware to industrial components, automotive parts, and decorative metal products.

Why Choose Taj India Machinery?

At Taj India Machinery, we focus on building machines that combine automation, precision, and performance. Our CNC Automatic Rotary Polishing Machines are developed with modern technology and robust components, ensuring high-quality results even under continuous operation.

Key Advantages:

-

High Precision: CNC control ensures consistent polishing results.

-

Increased Productivity: Multi-station rotary design allows simultaneous polishing.

-

Energy Efficient: Optimized power usage for cost-effective operation.

-

Durable Build: Designed for long-lasting performance and minimal maintenance.

-

Versatile Applications: Suitable for utensils, cookware, and metal components.

Our goal is to help manufacturers achieve a mirror-like finish while saving time, reducing manual labor, and improving overall efficiency.

Product Range

We offer a complete line of CNC Automatic Rotary Polishing Machines tailored to meet various production capacities and polishing requirements. Each model is designed to deliver precision, durability, and exceptional surface finishing quality.

1. CNC AUTOMATIC 4 STATION ROTARY POLISHING MACHINE (TI-RTRY-4AIR)

The TI-RTRY-4AIR model is ideal for small to medium-scale manufacturers who require consistent, high-quality polishing in a compact, automated setup.

Features:

-

Four polishing stations for simultaneous operation.

-

CNC-based control for precise rotation and pressure adjustment.

-

Air-controlled system for smooth, accurate movements.

-

Suitable for stainless steel utensils, bowls, and smaller components.

-

Compact design for easy integration in limited spaces.

This model offers an excellent combination of speed, accuracy, and affordability, making it perfect for growing manufacturing units.

2. CNC AUTOMATIC 6 STATION ROTARY POLISHING MACHINE (TI-RTRY-6AIR)

The TI-RTRY-6AIR is built for high-volume production where efficiency and finish quality are paramount. With six polishing stations, it ensures fast, consistent, and flawless surface polishing.

Features:

-

Six synchronized rotary stations.

-

CNC precision control for uniform polishing angles.

-

Air-based system for stable and vibration-free operation.

-

Handles various metal shapes and diameters.

-

Reduces polishing time significantly while maintaining premium quality.

This model is widely used in cookware, metal utensil, and hardware industries for bulk production.

3. CNC AUTOMATIC 8 STATION ROTARY POLISHING MACHINE (TI-RTRY-8AIR)

For industries demanding maximum output and superior finish quality, the TI-RTRY-8AIR model is the ultimate solution. It features eight fully automated polishing stations that operate simultaneously to achieve ultra-smooth, mirror-like finishes.

Features:

-

Eight-station rotary system for continuous production.

-

Advanced CNC control panel for precise programming.

-

Air-driven system for smooth, controlled pressure application.

-

High-speed, noise-free operation with durable polishing heads.

-

Designed for large-scale industrial production lines.

This model is ideal for export-oriented units, large utensil manufacturers, and metal finishing plants requiring high efficiency and uniform quality.

Benefits of CNC Automatic Rotary Polishing Machines

-

Superior Surface Quality: Achieves flawless mirror or matte finishes.

-

Automation Efficiency: CNC and rotary systems eliminate manual intervention.

-

Reduced Labor Cost: Minimizes human effort while increasing production.

-

High-Speed Operation: Multi-station design ensures continuous workflow.

-

Consistent Output: Uniform polishing and reduced rejection rate.

-

Eco-Friendly: Low noise and minimal power consumption.

Applications

Our CNC Automatic Rotary Polishing Machines are suitable for:

-

Stainless steel cookware and utensils

-

Kitchenware and tableware

-

Automotive parts and accessories

-

Decorative metal products

-

Industrial and hardware components

Whether it’s for mirror finishing, matte finishing, or edge polishing, our machines ensure outstanding results every time.

Conclusion

If you’re looking for the best CNC Automatic Rotary Polishing Machine Manufacturer, Taj India Machinery is your trusted partner. Our models — TI-RTRY-4AIR, TI-RTRY-6AIR, and TI-RTRY-8AIR — are engineered to deliver exceptional performance, durability, and flawless surface finishing.

With advanced CNC automation, robust construction, and efficient rotary technology, our machines guarantee the perfect combination of speed, precision, and quality.

Choose Taj India Machinery – where innovation meets craftsmanship in every polished product.